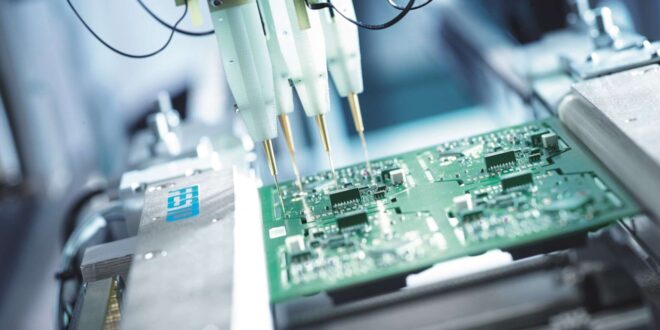

The demand for PCBs in the market is growing. This industry never stands still and is always ready for new challenges that will only enable even better results. Each of them is changing the future of the market and is relevant for all original equipment manufacturers. Of course, we must not forget some serious upheavals that have befallen us in the past few years, as they have contributed to production deficits. However, the manufacturing sector should not pay attention to them but put an end to these turbulences.

That is why it is crucial to plan and strive to make current predictions. To help you focus on this as best you can, we’ve created a list of emerging trends. We will try to provide you with an insight into all current topics that move between world manufacturers from a global perspective. Keep reading how you can participate in improving PCBs and learn more about efficient manufacturing methods.

1. ESD protection systems

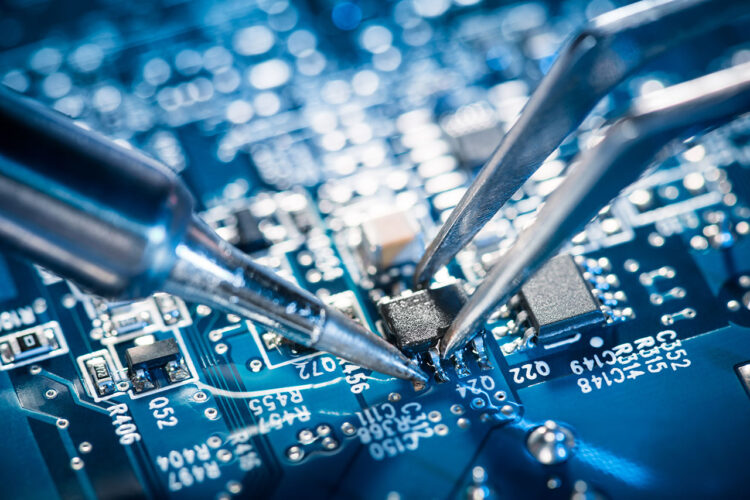

Of course, a much better job would be done if all components were protected. However, that is still not one hundred percent implemented and it is necessary to work on this. Your task as a responsible person would be to install this protection, and the great thing is that there is a line of ceramic substrates on the market that contains this.

2. High-power boards

We must not forget another priority, and that is the PCB of enormous power that everyone strives for. Today, many important technological solutions have appeared that can help you with this, but because of that, your appetites have also increased. The market will no longer be satisfied with low power, and anything above 45 volts is highly desirable. However, these levels require the installation of much larger components such as expansive battery packs. This way the devices would work much longer. On the other hand, plates that would support this must have certain characteristics. It refers to the ability, efficiency and power.

The problem arises when the nature of PCBs is taken into account, and this primarily refers to very small dimensions. These manufacturers simply have to reduce their products. However, the more powerful the thin parts, the more incredible heat they will be able to produce. That is why this is a condition for progress, but also a great challenge for designers. It is important to keep in mind the thermal design and heat dissipation.

3. Smart consumer devices

When we mention the dimensions of this board, they do not always have to be a problem, but quite the opposite. With the advancement of technology and the influence of the iPhone, we have come to miniaturization. That is how wearable technology became a complete hit, because it achieved integration, multifunctionality and much more. So, we can say that this is a kind of iPhone effect. However, over time, customers have had growing expectations that exceed reality. Their requirements can now be compared to some kind of science fiction, because they expect incredible functionality from IoT devices.

The PCB sector encounters a number of obstacles, and the Internet is certainly one of them. Given that IoT is present in almost all commercial industries, a lot is really expected from PCBs as well. This refers to the need for significant boards that push the boundaries of regular PCBs. This is exactly where the need for protection is concerned, and the existence of its more advanced forms. Very high standards are set that affect the development of this board.

4. Protect PCBs from cyber attacks

Speaking of PCB protection, we do not only mention that it is important to raise the thermal design to a higher level. There is something beyond that that requires much better planning, and that is achieving cyber security. It is the rapid growth of the Internet that has led to these attacks being our daily routine, which means that this board comes up with another challenge when it comes to networks. There are more and more situations in which there is falsification and deception. They knew that with the development of technology, we can only witness an even greater number of situations in which cybercriminal activities are represented.

The digital revolution has imposed a huge need for an increasing number of electronics, and each of them includes PCBs and connecting components. It is an opportunity for cybercriminals to find new ways to create an even more innovative design that will help them in their plans. It is, therefore, crucial to increase supply chain oversight and pay attention to all parties involved. The introduction of new methods and standards is another obligation in order to successfully identify vulnerable or false elements. This is especially important for companies like uetpcb that make custom PCBs.

5. Go-Green

Today, you attach great importance to environmental protection in many business sectors. Thus, the PCB industry also reminds us of the importance of protection for our own sake and for the overall quality of our lives. When we talk about environmental protection, it means that we understand the impact of all activities on it, and that is why we are continuously working on improving the PCB system. That is why one of the most important trends is adherence to the RoHS compliances. We must be aware that any concern for our environment is justified and that it is at the top of the list of problems we need to address.

Ecologically acceptable production processes are increasingly present in the industry, and the demand for lead-free products is equally high. These products will help to better protect users, but also reduce carbon production to a minimum.

6. 3D

This industry is also realizing the process of modernization when it comes to the implementation of modern technologies that rely on 3D solutions. So, one of the potential trends is 3D integration and built-in components, and that requires much smaller and denser boards. In this way, greater complexity is achieved as well as reduced production costs. It also contributes to the better performance of the overall system.

Conclusion

So, by using improved technology, we can greatly influence the improvement of this industry. It is already constantly evolving, and by adopting important production methods we can achieve a lot. However, we must not forget that improved technology means more costs. That is why it is very important to pay attention to this factor, but also to find a way to achieve balance and improve expertise in that scenario. We hope we have helped you learn more about the most important developments of today when it comes to the PCB manufacturing industry.

Hi Boox Popular Magazine 2024

Hi Boox Popular Magazine 2024