Overheating causes many engine failures. The internal combustion engine produces large amounts of heat and, while useful up to a point, too much can literally melt and warp metal components.

Cooling systems prevent this from happening while maintaining the high temperatures needed for combustion efficiency in cars pushing out more power.

Along with oil circulating through engine block passageways, these systems keep engines from quickly dissolving into a heated fireball.

How the Cooling System in Your Car Works

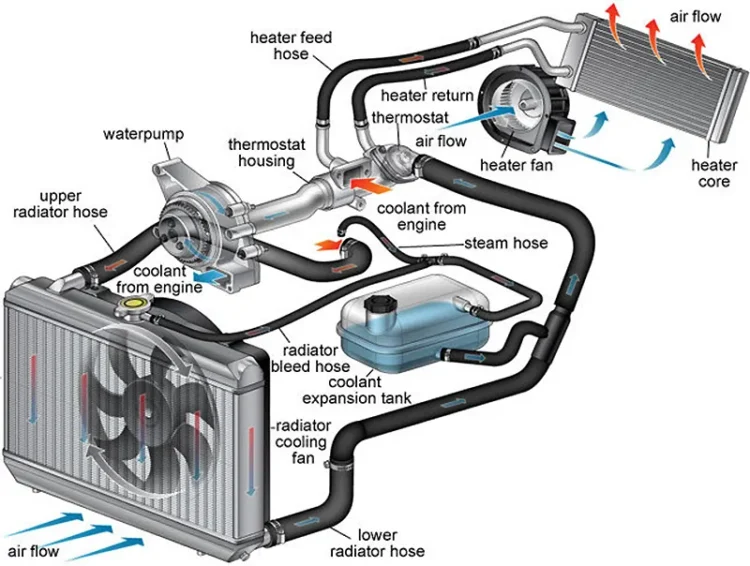

Apart from older cars (the VW Beetle comes to mind) and a few lower displacement motorbikes that rely on air cooling, most engines are liquid-cooled. These depend on circulating coolant to absorb heat from hot engine parts. This reaches the radiator where it’s cooled by oncoming air and with the help of fans, pushed through a network of hoses by a water pump, and circulated again for another cycle.

Additional parts also have a vital role. Thermostats located along the lines just before the radiator can open to let coolant pass when the engine is getting hot or remain closed until the optimal working temperature is achieved. This proves vital in efficiency and lowers fuel use.

Related are temperature sensors, often as an integral part of the thermostat or as a standalone unit near it to inform the car’s ECU of the coolant temperature and help with fuelling. Overflow tanks collect expanding coolant and pressure caps keep the cooling system under the same pressure.

What Radiators Are and What Do They Do?

Central to the cooling system are car radiators. They are also the biggest component and the one that’s instantly recognisable. These parts are often at the front of the engine bay. They serve as heat exchangers, dissipating heated coolant through a series of tubes and fins and helped by the ambient air entering through the car grille.

When the engine gets really hot, cooling can also be aided with electric fans to speed things up. The ECU operates these with prior info from temperature sensors. Once the coolant has passed through the radiator and cooled to a specified temperature, it can make another cycle through the engine. This way, the system prevents the car from overheating.

What Are the Different Parts of a Radiator?

Radiators consist of several parts, each with a crucial role. This includes the inlet and outlet tanks, the core and the pressure cap. Adjoining parts such as inlet and outlet hoses get the coolant in and out.

Inlet tanks collect hot coolant from the engine, guiding it towards the core. This consists of tubes through which the coolant passes and hundreds of attached fins that help disperse heat to the surrounding air. Once the liquid has cooled, it passes into the outlet tank and is ready to do another cooling cycle.

Since it’s a sealed system, there’s no loss of coolant. When this gets very hot to the point it expands, the built-up pressure in the system is regulated by the pressure cap. This opens to let pressurised air and coolant exit the system and be collected into an overflow tank. Its goal is to prevent damage to the radiator and connected hoses.

What Are the Different Types Available

Cross Flow vs Down Flow

Different design elements mean there are two major categories: cross-flow and down-flow. Cross-flow types have tanks located on both sides of the core. This saves space in smaller cars, with tanks lined vertically, and the core horizontally, and allows for wider units. The coolant travels right to left.

Down-flow variants have a vertically-positioned central core and an inlet tank above and an outlet tank below. Coolant enters at the top, is urged on by pressure from the water pump and gravity, is cooled through the tubes and fins and exits at the bottom. Both types are efficient in cooling the engine, assuming they are of the same size.

However, the often larger surface area in cross-flow types, and the fact that the coolant passes a greater distance and therefore is cooled to a greater extent make these more common in cars with higher heat generation, such as those fitted with turbos or with bigger displacement engines.

Down-flow types are more frequent in taller cars like SUVs but are also found in older vehicles. The type your car comes with is generally down to space issues, and the ability to position related parts like water pumps.

Single, Dual, Triple and Multiple-Pass

Cooling efficiency is also affected by the number of passes the coolant makes through the radiator core. In single-pass types, the coolant passes through the core only once before exiting through the outlet tank. Dual-pass systems are a bit more complex. These circulate the coolant through the upper parts, and then through the lower half to conclude a second pass.

This allows for a greater flow rate, so heat dissipation is greater. Triple and multiple pass radiators are recent additions, and allow the coolant to circulate through the core three or more times, in effect significantly reducing coolant temperatures. These are found in performance cars with high power output.

Materials

The use of different materials affects heat conductivity and how fast the liquid is cooled. This also impacts price. Generally, there are four types of automotive radiators in terms of materials – aluminium with plastic, brass with copper, aluminium, and plastic.

The most mass-produced are car radiators with aluminium cores and plastic tanks. These are low-cost options and adequate for most uses. Next up are old-school brass and copper versions, with brass in the tanks, and copper in the cores.

Recent innovations (with revised tubes and fins) have meant better heat conductivity than aluminium/plastic tanks but still fall short on strength and lack corrosion resistance, meaning added weight, more space and the likelihood of rust affecting how cool the coolant can get.

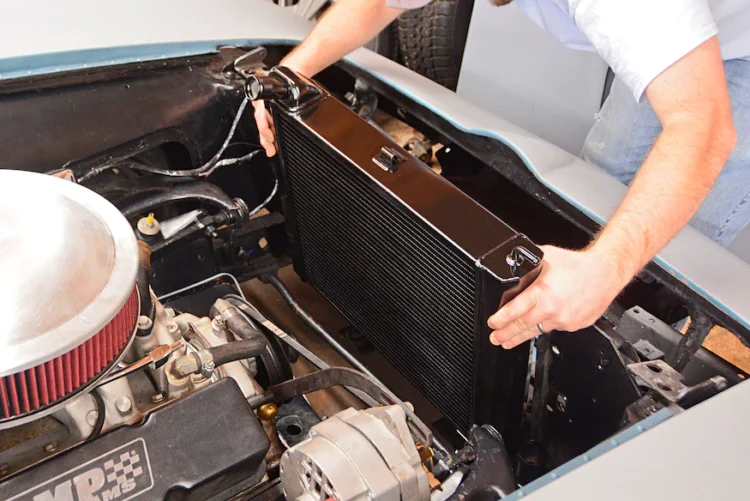

If you’re after high efficiency, then models made entirely of aluminium offer better conductivity than cheaper aluminium and plastic variants. They can handle higher coolant temperatures and higher pressures. They’re mostly chosen for in-car rebuilds and engine modifications that increase power (and hence heat). Lastly, plastic-only variants, have proven to be a viable alternative to brass and copper units, with lower cost, but will be harder to repair when damaged.

Signs of Damage

While high-temperature readings and overheating are obvious signs that there is a fault somewhere in the cooling system, there are also tell-tale signs that this could be the radiator itself. The most common is leaking coolant, This can be from cracks or leaks and coolant pooling under the car. Leaks are often accompanied by a sweet smell, so should be easy to spot. Periodically check the coolant levels. If these are low, time for a visit to your local mechanic.

Coolant that is oddly thick and discoloured is a sign of rust or debris contamination. This can further cause sludge buildup inside the radiator and will additionally affect performance. Moreover, damage to fins from road debris, gravel or other objects can affect airflow and cooling efficiency.

Other related issues are stuck caps, which quickly increase pressure and temperatures in the cooling system, with overheating soon to follow.

Pay attention to how your car performs in everyday driving conditions and weather. If the engine heats up quicker than usual or takes quite a bit of time to get warm, get the car radiator and the whole cooling system checked before major engine failure occurs.

Hi Boox Popular Magazine 2024

Hi Boox Popular Magazine 2024