Maybe you see metals and other products made from metals and wonder how they come about! There must be a very serious work behind it to make them appear the way they are today. The whole process takes a lot of science, technology, and energy from different parties. In this small brief, we are going to explain how metal manufacturing companies operate and how the process of making metals and steel goes about.

What do you need to know about metals?

A metal is any material that can transmit heat and electricity very well. In most cases, it’s defined as any material that, when polished, freshly prepared, and fractured, shows a very lustrous appearance. Many properties set metals aside from other materials.

As I have already stated, metal is a material that can conduct electricity at zero degrees. It’s also malleable, meaning it can be crafted and hammered into thin sheets. In some other situations, some metals such as aluminum, iron, and copper can be used to make electric wires.

Metals exist in two states, which are as a chemical component or a molecular compound. Metals of all types have been used for a long time. As a matter of fact, the history of metals dates back to about 11,000 years ago when people started using copper to make tools and other materials. Also, the use of metals is dated back to human civilization.

Other metals such as gold, silver, and iron followed after that as the demand for metals and the increase in their application skyrocketed. The metals that were in use at this time were very heavy, but in 1809, sodium regarded as the first lightweight metal was discovered. The development of more sophisticated metals dates back to the end of WWI.

So how do metal manufacturing companies operate?

It’s known that the earth is made up of about 25% of metals by weight. Out of these metals, the largest amount of them on earth is light metals such as sodium, aluminum, and magnesium. In the world, there’s a scarcity of some heavy metals, including copper and Gold.

Though, these metals exist in some extractable amounts, which is the reason why we have them in the market today. To get metals from the earth, you can expect that there’s a type of science and technology used.

Metal extraction

Metals are extracted from the earth by means of mining ores. These are the rich sources of requisite elements, including bauxite. Some methods, including exploration and examination, are used to locate mining ores.

In this regard, some heavy equipment is used to mine these ores and eventually convert them into raw materials. Chemistry is also applied to separate the metals from other elements.

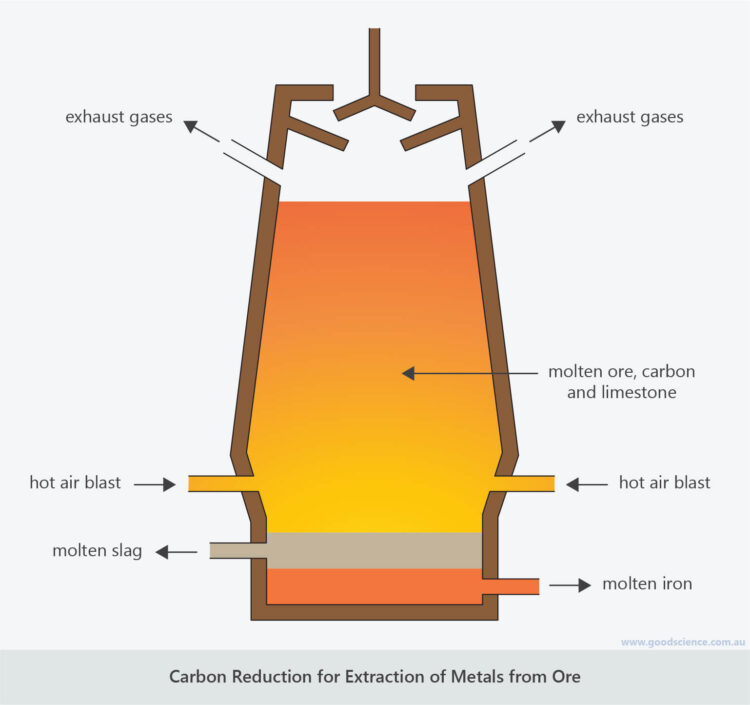

The ores are heated with a reducing agent to get pure metal from its ionic compounds and non-metal materials. There are many types of smelting agents used, but in this case, iron or carbon is the major reducing agent. When reducing some other types of metals such as sodium and aluminum, it’s extremely difficult to get a specific reducing agent. What this means is that other types of methods are used to extract them, such as electrolysis.

The steel production process

Over time, the methods that were used to make stainless steel and other steel products have evolved significantly. This doesn’t mean that modern methods are not connected in any way to the older methods.

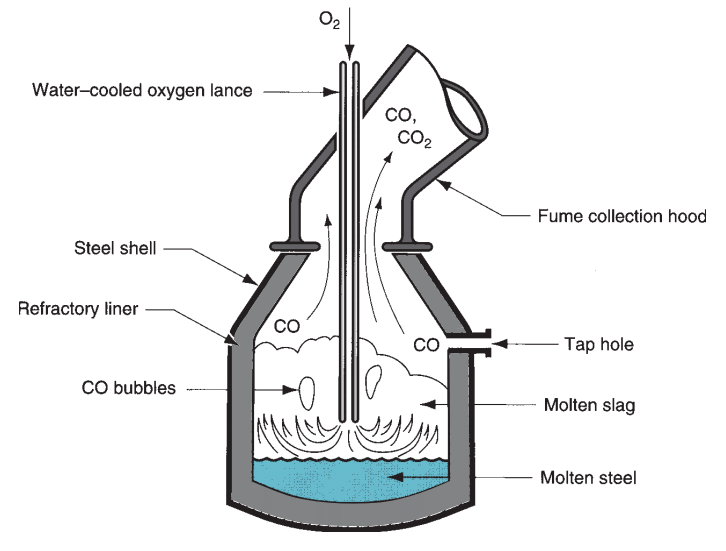

Most of the modern methods are still based on the use of oxygen to reduce the amount of carbon in the metal. To make steel, most companies today don’t use pure iron. Most of them are targeting recycled materials, which are also a good way to conserve the environment. They are now using limestone, coal, and iron ores as well to get the steel.

Methods used

There are two very common methods used in making steel. These are the electric arc furnaces (EAF) and Basic Oxygen Steelmaking (BOS). In any of the processes, the first step involves the process of inputting raw materials, which are iron, coke, and lime. They are all being melted in a blast furnace.

The resultant substance is known as hot metal, which has about 4.5% of carbon and many other impurities. This is clear that another process to remove carbon and these impurities must be started.

Removing Carbon and Impurities

In the process of BOS, recycled metals will be added to the hot metal, and oxygen will be blown over the metals to reduce carbon content significantly. On the other hand, the recycled steel scrap will be fed through high-power electric arcs to make the metals melt. This will eventually be converted to high-quality steel.

Several other steps will be taken to treat the molten steel produced from any of the methods to regulate its configuration. For this to become a reality, several elements can be removed from the metals. It can as well be done by manipulating the temperatures and production environment.

What can other methods be implemented?

What makes the difference here is the type of steel that is required. With that in mind, any of the below methods can be used to alter the composition of the steel.

● Ladle Injection

● Stirring

● Degassing

● CAS-OB

● Ladle furnace.

Manufacturing, Fabrication, and Finishing

Depending on the desired shape and the size of the steel needed, many secondary forming techniques will be implemented. They include the ones stated below.

● Shaping

● Drilling or rather machining

● Welding or joining

● Galvanizing or coating

● Tempering or heat treating

● Carburizing or surface treatment

Some metal applications in flex metal hoses and other tube bending welds. You can learn more at Aero-Flex Hose Manufacturers.

After everything else is done, the metals can be used to make different materials. Today, metal manufacturers are making metal hoses using stainless steel. The hoses are quite durable and strong, a reason why they are preferred in transporting heated substances under high pressure.

The process of making any metal depends on the specific qualities and the intended applications. This is actually the case with the last steps of reshaping and joining.

Hi Boox Popular Magazine 2024

Hi Boox Popular Magazine 2024