Heat exchangers are devices that are used to transfer energy between two fluids that are at different temperatures. They can improve energy efficiency, because the energy that is already inside the system can be easily transferred to some other part of the process, instead of just being wasted by being pumped out. In this new era of sustainability, the growing need to save energy and to reduce our overall carbon footprint has placed a great emphasis on the use of heat exchangers with improved thermal efficiency. In this new scenario, plate heat exchangers can play a very vital role.

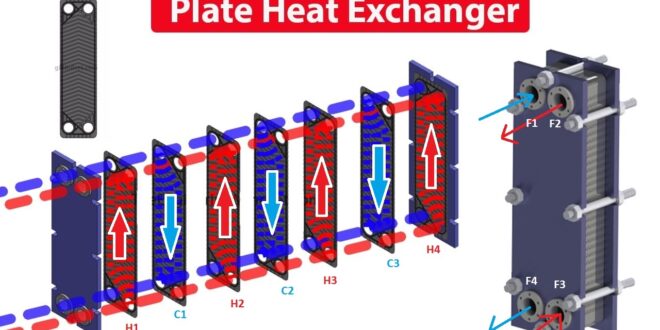

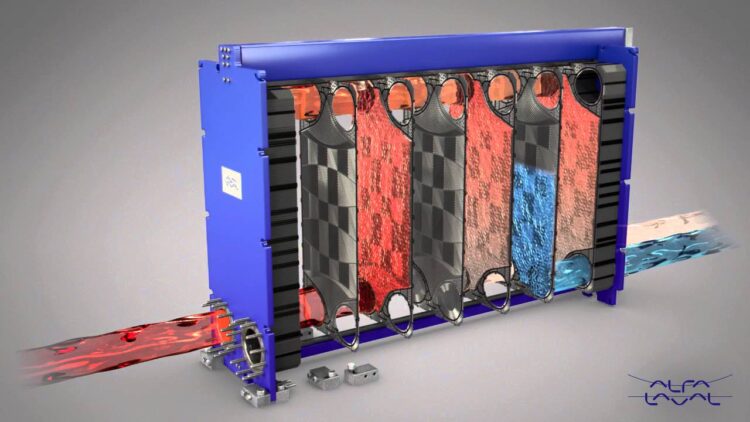

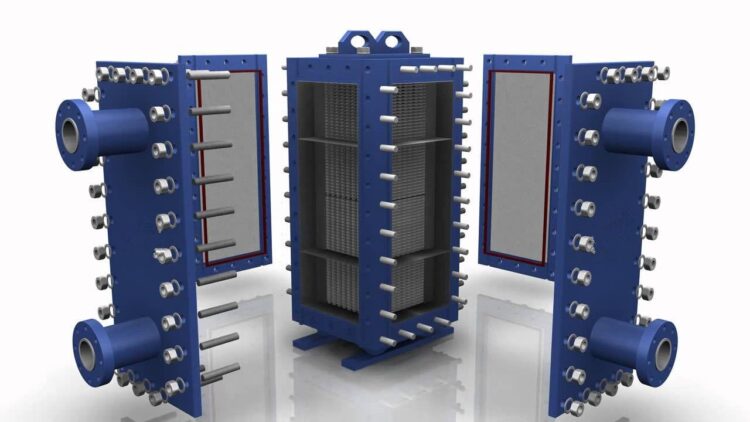

A plate heat exchanger is a compact kind of heat exchanger that uses a series of metal plates to transfer heat between fluids. There are four types of plate heat exchangers: brazed, welded, semi –welded and gasketed. The gasket or plate-and-frame heat exchangers usually consist of a pack of thin metal plates that are sealed around the edges by gaskets and are held together inside a frame.

Plate heat exchangers were first introduced in the 20s and were used for milk pasteurization applications, however, today are used for a lot of applications in the petroleum, HVAC, dairy, pharmaceutical, liquid food and health, beverage, chemical, and refrigeration care sectors. This is because of the unique advantage of plate heat exchangers such as the flexible thermal design, good temperature control, ease of cleaning to maintain hygiene and much better heat transfer properties.

Types of plate heat exchangers

Gasketed plate heat exchanger

These use high-quality gaskets and design to seal the places together to protect from any leaks. The place can be easily removed for expansion, cleaning or replacing purposes which drastically reduce maintenance costs

Brazed Plate heat exchanger

These are used in a lot of refrigeration and industrial applications. Because of its stainless steel plates with copper brazing, they are very resistant to corrosion. Brazed plate heat exchangers are compact and efficient, making them a great economical choice.

If you want to know more about heat exchangers, make sure you click here.

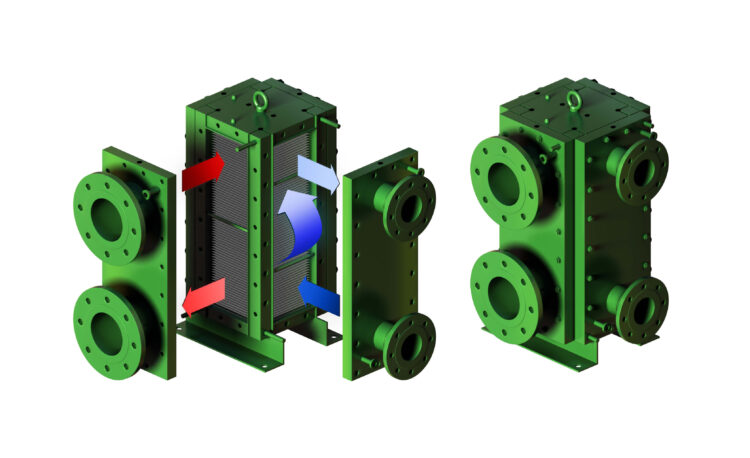

Welded plate heat exchanger

Welded ones are similar to Gasketed plates, but instead, the plates are completely welded together. They are very durable and are perfect for transferring corrosive materials or for transferring fluids with high temperatures. Since the plates are welded together, cleaning of these plates is not possible as with the other types of plate heat exchangers.

Semi-Welded plate heat exchanger

These feature a mix of gasketed and welded plates. They contain pairs of two plates welded together who are then gasketed to other pairs of two, therefore one fluid path is welded while the other fluid path is gasketed. This results in a heat exchanger that is able to transfer more intense fluids on one side while the other one is easy to service. These Semi-Welded heat exchangers are great for transferring expensive materials since they offer a very low risk of fluid loss.

There are a lot of advantages you can get out of plate heat exchangers. Especially since they are compact in design, they are very easy to maintain and clean since the plates are easily removable and they also have great temperature control.

Hi Boox Popular Magazine 2024

Hi Boox Popular Magazine 2024