Die Cutting has a wide variety of uses from consumer bought die-cutting machines used in the home in the field of arts and crafts to die-cutting companies using huge die-cutting machines that supply unlimited supplies for unlimited products made for a wide range of uses and fields.

Any private consumer who wants to replicate the same item for an arts and crafts project can purchase a die-cutting machine to use in the home. This machine uses a template to produce the same item in specific amounts. Templates are available online in hundreds of styles and shapes. This machine can produce replications with sharper images then the sharpest of scissors and in a lot less time.

A company whose expertise is die-cutting can be contracted to cut out the same item in the thousands. Many industries utilize the skills of a die-cutter when a product needs replication in the hundreds or tens of thousands. Industries such as the following are likely to hire a die-cutting company to replicate their products.

. Medical

. Aerospace

. Automotive

. Electronics

These and more industries rely on the expertise of a die-cutting business to produce many of the products used in that specific industry.

For example, one industry that relies on die-cutting expertise is found in the medical arena. There is an endless list of medical tools are produced for repeated use or disposable products for one-time use only. The medical industry uses untold replicated items numbering in the thousands.

These die-cast companies can use any number of materials that range from silicone or synthetic rubber, acrylic, polystyrene, polypropylene, plastics, stainless steel, aluminum, polycarbonate, and polyethylene to mention a few of the materials used by these die-casting companies.

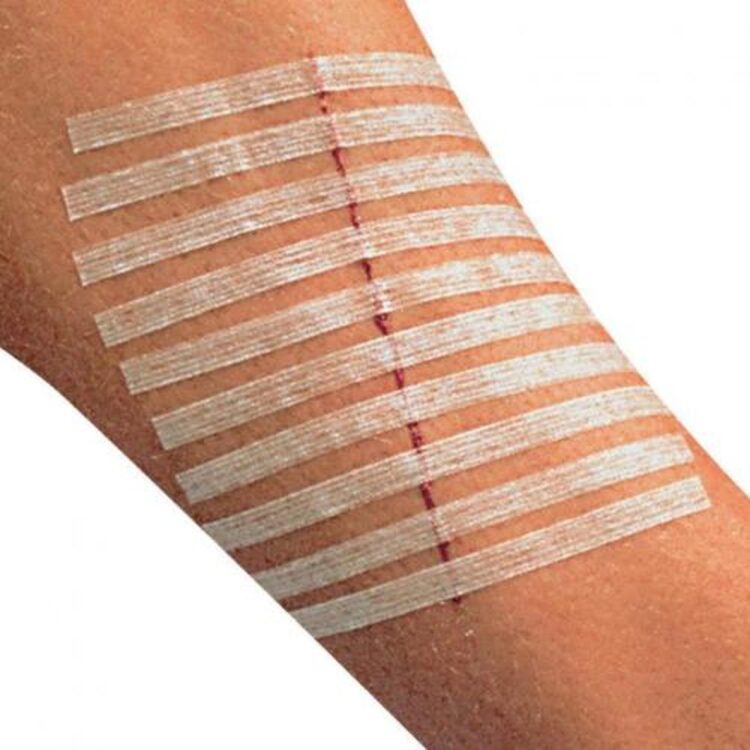

As an example of a fabricated medical product is one such small and seemingly insignificant, yet in-demand medical product. Die-cutting companies engineer, design, and supply sterile wound strips used on the skin to bring the edges of a cut, or surgical incision together. The use of sterile wound strips helps the patient avoid traditional sutures done with a needle and nylon thread.

Sterile wound strips are very much in demand because these sterile wound strips can reduce a patient’s risk for infection, speed healing of the wound, and remain friendly to the patient’s skin. There has to be a way that the medical industry can order thousands of these strips that are prepackaged and sent to the medical offices, hospitals, clinics, medical facilities, and even retail store outlets for individual consumer purchase, and much more. It is the die-cutting company that can fill this demand and this is only one of the many thousands of products coming from a die-cutting company.

Many different types of medical instruments are now produced in the tens of thousands by die casting companies as disposable instruments and meant for one time use by medical staff throughout the global network. Trending in the 21st Century is the increased use of polyolefins by casting companies.

Rotary Die Cutting

There are two types of rotary die-cutting, flexible and solid dies which are both cylindrical. The flexible is made of thin sheets of steel. These metal sheets wrap around a magnetic cylinder. The solid die is a solid steel cylinder which is used for extended die life.

There are specific materials used by rotary die-cutting companies that include paper, silicone, cloth, fabrics of all types, and PVC. Not all die casting companies are set up to produce replicated items using the same materials. These companies can provide design assistance, prototyping and produce short runs or higher volume orders and inspection of end products.

Some of these companies use only certain materials compatible with their machines for custom rotary converting and tooling. Materials may include semi-rigid materials from stock, films, fabrics, foils, paper, rubber, foam, tape, and silicones. These companies can convert, design, score, and slit products.

A rotary die cutting company such as RDMedicalProducts can produce a small or larger volume of products that may range in various sizes depending on their machinery such as, from one inch to over a hundred inches. These companies can cut parts ranging in size of twelve to 24 inches in length to a thickness of 0.001 to 0.010 inches. Cutting machines are different and each die-cutting company offers something different.

The specific techniques used in rotary cutting include creasing, heat sealing, ultrasonic sealing, vacuum transfer, laminating, folding, embossing, poaching, chilling, stacking, do color printing, slitting, and weeding, such as used in medical disposables.

Rotary services offer clients the ability to mold, convert, prototype, sheeting, kitting, perforating, do multi-layer laminations, and gasket manufacturing to mention a few services offered.

Many die-cutting services work with the following, including pressure-sensitive materials,

. Fabric

. Felt

. Fiberglass

. Silicone

. Urethane

. Chipboard

. Foam

. Neoprene

. Orientated Strand Board

. Polyester

. PVC

. Rubber

How the Rotary Die Cutting Company is used for Medical Components

The medical industry uses thousands of products that require fabrication from roll stands, rotary cutters, and processing systems. These companies rely on the expertise of engineering, and trending designs in the latest manufacturing facilities available. The dedication to customer service must be unparalleled.

Rotary processes include systems that are sanitary and washable, innovative, and precisely engineered by experienced and seasoned teams of professionals to design and produce all sorts of,

. Medical Devices

. Pharmaceutical Supplies

. Wound care supplies

. Products to Enhance Drug Delivery Systems

. Diagnostic Equipment

. Cosmetic Products

. Surgical Applications

. Patient Care Products, and much more.

Call to Action

The medical industry is always in demand for untold and varying medical applications. It is the rotary die-cutting company that fulfills the ongoing and trending need for medical products required within the particular medical field from dental offices to all kinds of medical offices, clinics, hospitals, specialty hospitals, doctors’ offices, surgical centers, and many more medical entities.

Most supplies are engineered, designed, cut, and packaged at a quality rotary die-cutting company. All medical tools and applications from the smallest bandage to the largest surgical tool come from a die-cutting company. Although medical application trends and are constantly updated and changing due to advancements in medical technologies, it is the rotary die cutting company that must keep the demand for medical equipment, tools, and applications flowing.

Hi Boox Popular Magazine 2024

Hi Boox Popular Magazine 2024