As robotic or robotic-assisted services and products are going through a boom in the last couple of years in the industrial and commercial worlds, and especially in the automotive industry, it is a smart idea to start profiting on these services. If you are willing to enter this world of robotics, it is crucial to understand the types of robotic joints, how they are used in robotic arms and where robotic arms are used.

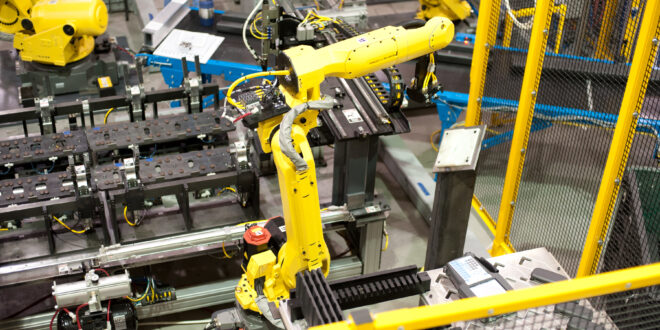

These robotic arms are used almost anywhere where there is a need for faster production or automatization. They are especially famous in the automotive industry because it can be used to handle any heavy metal or other heavy materials, painting body parts, drilling hard materials or hard to access locations, welding and more. With the invention of the mechanical joint, the robotic arm is able today to make faster and more precise movement than a human can ever do. They are also used to replace humans from hazardous positions such as handling extremely radioactive materials, repairing cables or pipes on the ocean floor, handling high voltage circuits and more.

By using these robots, we are increasing the overall quality of every product, especially when it comes down to vehicles. This benefits both the consumers and the companies since the number of on-site injuries is considerably reduced, less stress on the workers since they do not have to work on such precious and heavy materials. They are also much cheaper to maintain than hiring workers and worrying about their health. Robotic arms can also work on cars almost 24/7 without needing a single pause during those hours and without their quality of work ever dropping. According to Rozum, robotic joints and arms are what increased the overall quality of the automotive industry.

However, all of this wouldn’t have been possible if we didn’t find a way to properly develop the mechanical joint.

Types of mechanical joints

Such joints are a way to connect two mechanical parts together giving them the ability for much more freedom in their movement. Most of these joints are inspired by how human joints work. Our shoulders, knees, hands, feet, and hips are all a huge inspiration to this industry. Here are some of the types of joints you should know about.

-

Knuckle

This one is one of the first ones we have invented and is much more simple than what we use today in the auto industry. These are used when there is a need to connect two bars under some tensile load.

-

Pin or Revolute

These are actually used in our everyday lives. Mostly used indoor hinges to release the latch holding the door closed.

-

Cotter

These are usually used to enable axial direction, but without giving any rotational freedom. These can also be under tensile or compressive load.

-

Ball

These are more advanced types of the joint that are usually used to connect the wheel steering of a vehicle to the control arms which gives us the ability to give the wheels a direction. This one is heavily inspired and designed by the work of a human hip.

-

Prismatic

This is the most advanced type of joint we have invented and are heavily used in robotic arms. This is what gives such arms the human-like dexterity and precision.

Hi Boox Popular Magazine 2024

Hi Boox Popular Magazine 2024