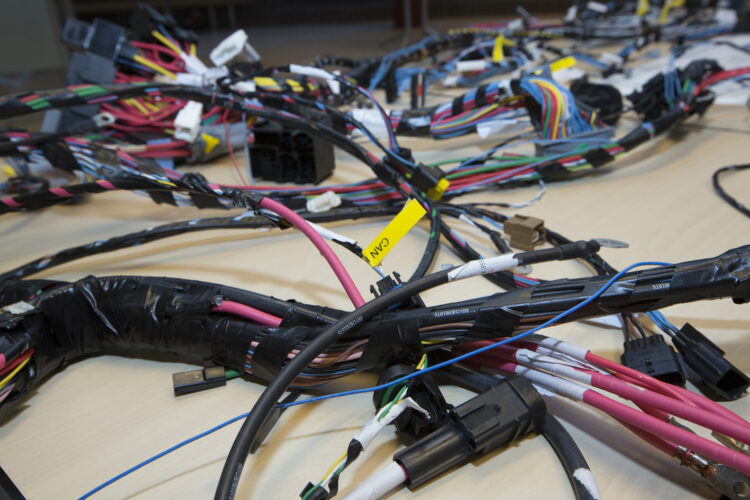

You put in a lot of effort to design and create a reliable wire harness for your heavy-duty machinery. It only makes sense to put in the same effort to protect it from the working environment so that it can continue to perform properly for the duration of the machine’s life. It poses the question of how to safeguard something that can be so complicated.

There are various potential answers to that topic. Let’s compare some of the most popular wire harness protection strategies, which are mentioned below:

1. Snap Together Enclosure

The most basic type of enclosure is the snap-together enclosure. It’s the ideal combination of strength and accessibility, allowing you to snap it together and apart as needed for maintenance or replacement. The snap-together enclosure is the best option if your wire harness assembly will need to be maintained or adjusted regularly. It will give experts instant access and will remain stable when they need it to work.

2. Screw Together Enclosure

This is one of the safest kinds of enclosures, especially if the cable assembly is in a location where individuals who shouldn’t touch it may access it. Access is limited by putting the harness into a screw-together enclosure, which makes the enclosure more secure. It is easily accessible to those who want it, making it ideal for cable assemblies. However, it requires servicing or adjustments on a regular basis.

3. Ultrasonic Wave Enclosure

Ultrasonic welding enclosures provide the maximum level of protection. These enclosures are made to keep cables safe in a variety of situations, including tampering. The enclosure is effectively sealed around your cable assembly, making it nearly impossible to access without shattering the enclosure.

It’s made for cable assemblies that must be kept contained at all times in a volatile environment, such as a location where water leakage is a possibility. These enclosures are popular with safety officers since they are difficult to tamper with and can be immediately inspected whether an enclosure is safe to operate or not.

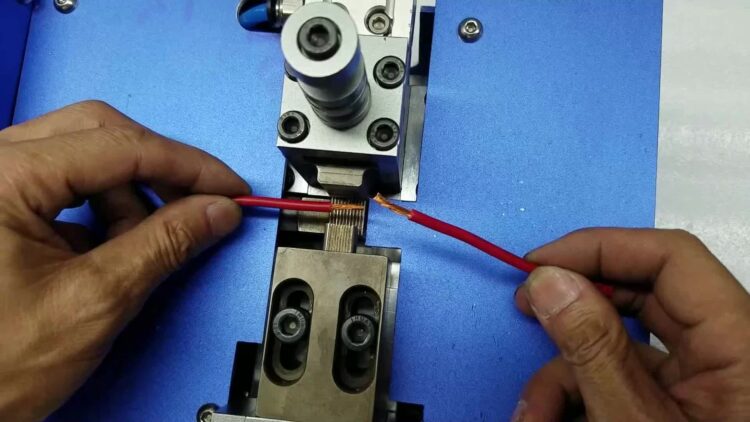

4. Braided Loom

The wire harness is wrapped with braided PVC-coated nylon in a looming machine, which provides flexible heat and vibration protection in a variety of heat resistance grades. To further protect the harness from electromagnetic interference, copper loom solutions are offered. Water can also pass through the braided loom, which is significant if the machine will be exposed to freezing temperatures.

It’s a single piece with no extra tape or zip ties because the nylon is braided directly onto the wire harness. Furthermore, the PVC-coated nylon is available in a variety of colors that can help your business stand out.

If you are looking for professional wire harness manufacturers, you can contact Scondar. They are known for providing durable wire harnesses, which can be used across various segments of your industry.

5. Convoluted Tubing

Convoluted tubing is available in a variety of polymers with varying heat and chemical resistance ratings. The tubing is liquid-tight and can be used with a variety of connector backshells. Convoluted tubing comes in a variety of diameters which allows the wire harness to be flexible. The tubing is also available in various colors to perfectly complement the branding aesthetics.

The wire harness will have to be fished through the tube and any appropriate fittings. For complex wire harnesses, this can be highly challenging. If you don’t use fittings at branch intersections, you’ll have to fasten the tubing using electrical tape or zip ties, as each branch requires its own piece of tubing.

This may have an impact on the liquid-tight seal. Before attempting to fish the harness through the tubing, make sure the wires are securely taped together with different branches clearly separated, just like a braided loom.

Tips For Wire Harness Protection

- The main power supply line from the battery to the remainder of the system must be safeguarded with either a proper gauge fusible link or a proper sized maximum fuse.

- The suitable size fuse or circuit breaker should be used to safeguard each individual circuit within the wiring harness. If an issue occurred, the correct size tail and park lamp fuse would safeguard these circuits.

- Every circuit requires a wire that is of the correct size for the expected electrical load. If you install halogen headlights in your vehicle but use a headlight circuit with insufficient wiring, you’ll have issues with heat and power loss . In this case, serious harm is always a possibility.

- The system, as well as the vehicle structure, must be grounded appropriately. You can have a variety of problems with various systems if your vehicle is older or incorrectly grounded (from ignition to the stereo). If you suspect any faulty grounding, a ground kit is an excellent choice.

Conclusion

Wire harness protections vary by industry and are mostly determined by the manufacturers and the type of industrial segment. This is due to the fact that each of the products caters to the individual needs of the applications in the many industries while also offering the necessary protection and flexibility.

In any event, items from reputable manufacturers must meet all of the standards of various industrial applications. This alone ensures that the items are of high quality and will endure a long time.

Hi Boox Popular Magazine 2024

Hi Boox Popular Magazine 2024