To weld is to permanently connect two different pieces of metal by melting them with a high enough temperature. There are at least ten things around you that have probably been welded one way or another. If you are in your work’s office, then you are probably sitting on a desk that had its feet welded together, the same applies to your office chair. If you are at home than all the metal shelves or basically anything that is built from metal has probably been welded at some pint.

This really shows how much this skill is needed in the everyday world, so if you are interested in learning this skill and providing in the industry and make some cash, there are a set of tools you must have if you want to be successful with your future project.

However, before we tell you about all the tools you need and before you run into the hardware store to buy everything at once, you will also have to consider the different types of welding. Because all of these different methods require other types of tools and equipment.

Types of Welding

Shielded Metal Arc Welding or SMAW

You have probably heard of this being referred to as stick welding and is probably the easiest method, most popular and is very common. You can see that it is often used in construction or when working on pipelines. It used a high enough electric current that goes from the “stick” to the metal which causes the metal to warm up to high enough temperature so it can be easily manipulated or in this case, welded to another piece of metal.

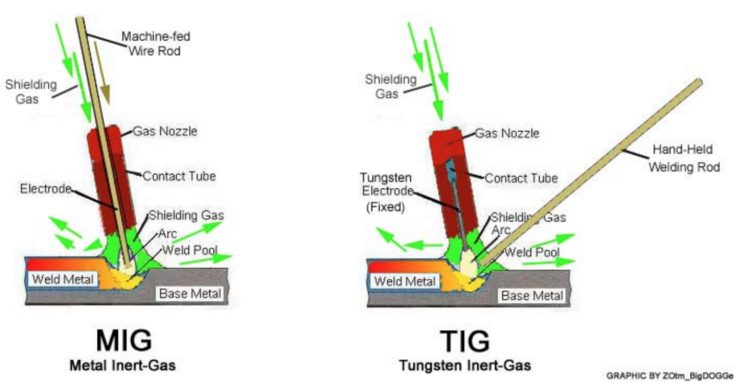

Gas Metal Arc Welding or GMAW

This method is also pretty easy to master and can be used on all kinds of metals, so if you are looking to get skilled for a more general direction in this industry, GMAW is the way to go, for sure. There are also a bunch of portable MIG welders which means that you will transport your tool much easier.

Flux Cored Arc Welding

This is considered to be a more complex method, but it is the preferred type of welding because of its efficiency and its speed.

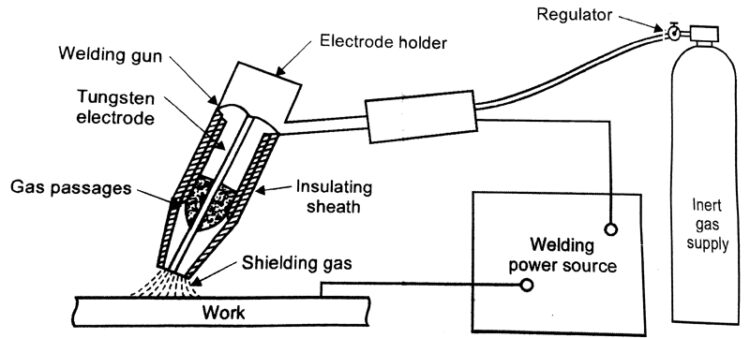

Gas Tungsten Arc Welding

This method provides the most durable and high-quality welding projects, although you will have to spend a bit of time to master such skill and it is also recommended that you also have a bit of skill in the other methods.

Now that you know about all the different ways you can weld metal and after you have finally picked which one is the right for you, here are some of the tools that are a must when learning such a skillset.

Surface to work on

The first thing you will have to supply yourself with is a place and surface that will be big enough where you can work on your projects. You can just set up shop inside of your garage and then work on your projects on the floor. It can be dangerous, impractical and can be even worse for your knees, back or neck. So, if you want to do everything safely, you will have to get yourself a workbench. According to https://www.welding.com.au/, you cannot provide your customers with high-quality welds if you do not work in the right environment. In this case, the right environment is the workbench.

While this might not be a tool, we recommend that you avoid saving money on this, as such as table will prove useful and durable for many years, so you probably won’t have any reason to ever change it.

Protect your eyes

When working on a project, it is very important that you protect your faces from the sparks that fly out of the metal, but you will also have to protect your eyes from the bright flashes of the torch. Every single welder on this planet has at least a few helmets with different types of dimmed glass.

However, if you are just starting out we recommend that you get yourself a helmet with an auto-dimming lens which can help you see easily on the project you are working. Most helmets in the past had a constantly dimmed lens which made it hard to be precise while working n the metal.

Protect your hands too

While your face and your eyes might be more precious than your hands, you should definitely protect this asset too. Your safety is the number one priority when welding, so don’t ever save money on such equipment. Keep in mind, you can’t just go to your closest hardware store and buy a bunch of gloves. You require a special set of welding gloves that have been tested and proven that they will keep you safe from all the dangers that come when working with a torch.

The temperatures of the arc from the torch can sometimes reach more than 10,000 degrees. Now imagine a spark that is only half of that temperature touch your skin. Yeah, doesn’t sound all that great now does it?

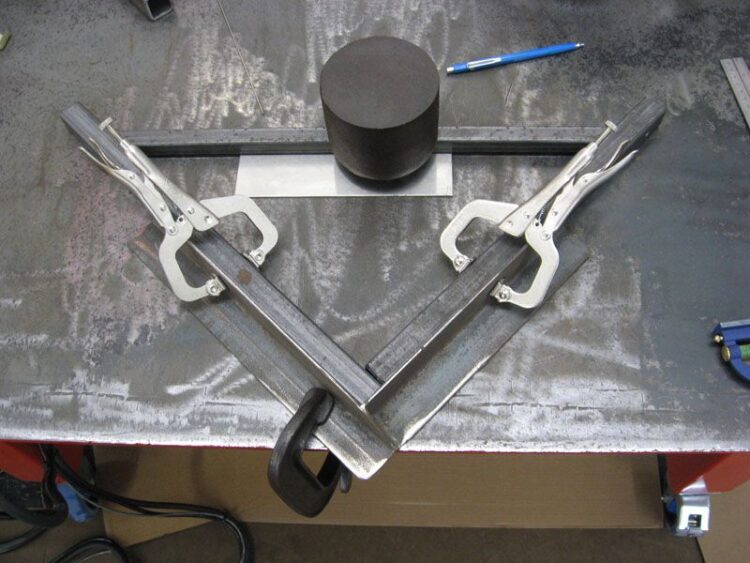

Something to clamp down

Just placing a piece of metal onto your workshop is sometimes not enough, especially if the metal part is pretty light. Both of your hands will be busy while using the torch which means that you will need something to hold down that piece for you.

A set of clamps is an essential tool for every welder. Sometimes you might need just one clamp, other times you will need more than 5 to properly hold down your project because even the slightest bump could ruin everything that you worked on.

A set of stainless steel pliers

While this might not be the most essential tool that you need for your work, it is still something that you will find handy while working on your projects. These can give you a lot of versatility because you will be able to easily manipulate the heated metal.

Hi Boox Popular Magazine 2024

Hi Boox Popular Magazine 2024